WHY push the white jacketing for PDM US Products?

There are a few key points that make the difference for me as a manufacturer’s rep/consumer/lover of the environment, that I think are pertinent to both our wholesalers and contractors. In my opinion we don’t push the jacket we are pushing the brand. PDM US is an awesome manufacturer who is not only a leader in manufacturing products that are sustainable using automated technology they are also a leader in testing, certifications and research.

PDM US started out with manufacturing the white line sets and was the leader in introducing the white in the US Market. The white jacketed product is where the focus has been and will be in; product development, testing & certifications in addition to volume which allows us to keep pricing and lead times competitive.

Why PDM US?

• Partner. A company that stands behind their product and is an innovator in performance and technology while maintaining a key focus on sustainability.

• Durability. PDM polyethylene internal foam and protective outer jacket make our solution extremely tough.

• Buy American. 100% Made In the USA

• Quality Copper. ASTM-B280/700 PSI 410 Copper

• Insulation Process. Unique machinery driven insulating process yielding No Gap- No Condensation

• Superlative R Values. We achieve higher R Values with less insulation due to technology advances allowing our wholesalers and contractors to offer more competitive pricing on jobs specified by R Value opposed to insulation thickness.

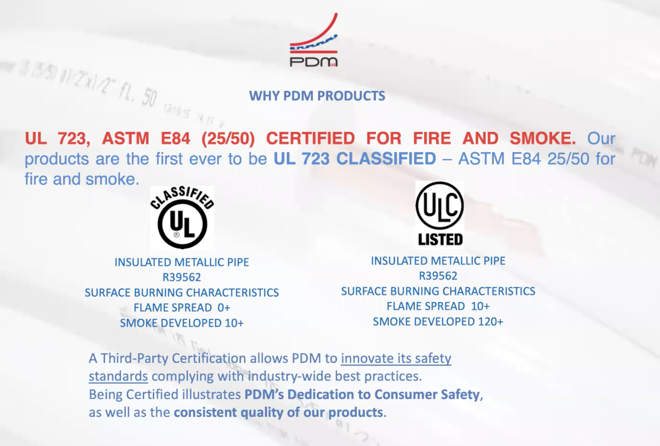

• Testing. Not only are we UL tested but we are UL certified which means our factories are inspected by UL to insure QC in production. We are also able to put the UL marking on our Product.

• UL Performance Verified for UV. Our product is guaranteed for 5 years from major degregation by UV.

• Paintable. Our shiny white product can be easily painted to match the surrounding

• Foot Marking. Accurate initial unit charge on jacketing

• 164’ Rolls

• Sustainability. Copper Recycling that avoid CO2 emission for 200 ton. Plastic recycling, we currently avoid CO2 emission for 300 ton. (To replenish 500 Ton/Year of Co2 you would need to plant 2500 trees!

• Dedication to Human Health. All PDM products comply to the most stringent health standards and requirements. The products are 100% Red List Free and include no chemicals listed in California Prop 65

In summary PDM White Poly Line Sets are better for the environment than Black Poly because Carbon Black is a colorant. Sustainability is very important to PDM as a manufacturer which is why they invest funding in developing of products that have the least environmental impact as possible not only in their composition but also their manufacturing process. This is also the reason that PDM has invested in testing and certifications for the White Poly which include performance verification and ratings pictured above. PDM is additionally in full collaboration with Clemson University for third party testing and research.

PDM US is a company that stands behind manufacturing quality product with the least amount of environmental impact.